Table of contents

Popular Machine Operator Resume Examples

Entry-level machine operator resume

An entry-level resume for a machine operator should focus on relevant technical skills, safety training, certifications, and any hands-on experience to demonstrate readiness for the role despite limited work history.

Focuses on goals: The applicant emphasizes their dedication to professional development by successfully operating machinery at high efficiency, optimizing production processes, and earning industry certifications that showcase their commitment to continuous improvement.

Prioritizes readability: A clean and straightforward simple resume template improves readability, allowing employers to identify this candidate's key qualifications.

Mid-career machine operator resume

A mid-career machine operator resume should emphasize a combination of technical expertise, operational experience, and continuous improvement efforts to effectively demonstrate career progression and value to potential employers.

Balances skills and experience: This applicant's resume showcases a robust mix of technical skills in machine operation and notable career advancements, illustrating their commitment to efficiency and quality throughout their professional journey.

Begins with a powerful summary: This resume's professional summary effectively highlights essential qualifications by showcasing extensive experience in CNC operations and process improvements.

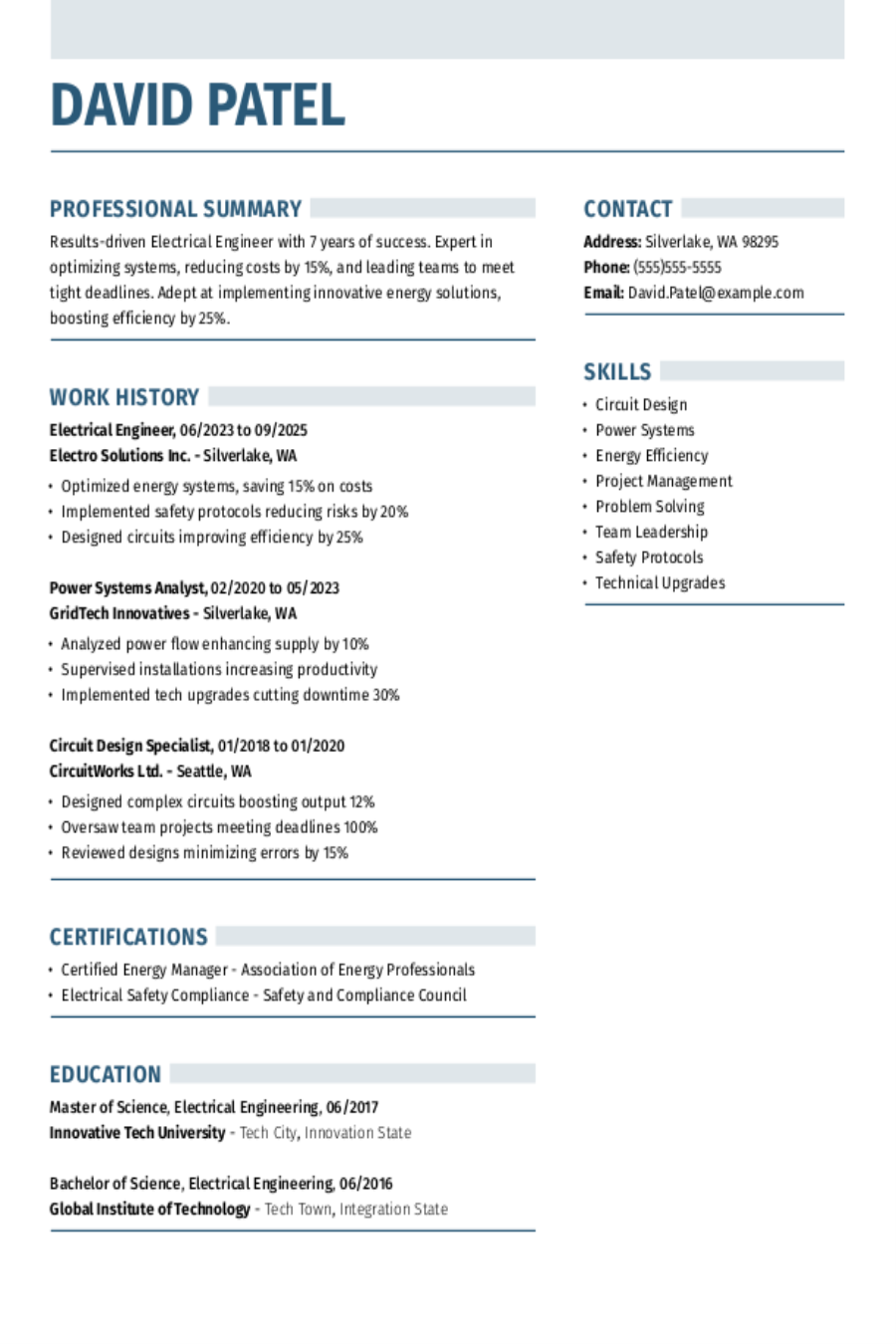

Experienced machine operator resume

An experienced machine operator resume should prioritize highlighting relevant skills, certifications, and key achievements to effectively demonstrate the job seeker's professional growth and expertise in the field.

Optimized for ATS: The resume uses a structured template that combines a professional header with an ATS-friendly resume layout, making it easy for both human recruiters and automated systems to navigate while effectively showcasing qualifications.

Embraces modern design: This modern resume template showcases the job seeker's innovative mindset and highlights their professional brand as a results-oriented machine operator committed to efficiency and continuous improvement.

No experience machine operator resume

A resume for an applicant with no experience should highlight relevant skills, certifications, and any hands-on training to showcase the job seeker's potential and eagerness to succeed as a machine operator.

Uses a simple style: This resume's straightforward layout effectively highlights qualifications, showcasing relevant experience and education without unnecessary distractions.

Overcomes lacking experience: Including extracurricular activities and volunteer roles improves this resume, showcasing practical skills and teamwork abilities that may not be highlighted through limited professional experience alone.

More resume examples

Machine Operator Resume Template

Looking to create a standout application? This machine operator resume template provides a solid framework that you can easily modify with your personal details and experience.

Ming Li

Tacoma, WA 98401

(555)555-5555

Ming.Li@example.com

Professional Summary

Results-driven Machine Operator with 5 years in high-tech production. Expert in CNC operation, increasing efficiency by 25%, and reducing waste by 15%. Proven track record in training emerging talent and leading successful lean manufacturing initiatives.

Work History

Machine Operator

Technic Manufacturing Co. - Tacoma, WA

October 2023 - October 2025

- Operated CNC machines, reducing waste by 15%

- Improved production line efficiency by 25%

- Trained 10 new operators, enhancing team capabilities

Equipment Technician

Precision Tools Inc. - Silverlake, WA

August 2021 - September 2023

- Maintained assembly equipment for 30% uptime

- Developed tool maintenance protocols, saving $5K/year

- Implemented 5S in workshops, boosting safety 20%

Production Assistant

Quality Fabrication LLC - Silverlake, WA

January 2020 - July 2021

- Assisted in machine calibration, reducing errors by 10%

- Optimized supply chain inventory, cutting costs 18%

- Collaborated with engineers for process improvement

Skills

- Machine Operation

- CNC Programming

- Quality Assurance

- Technical Maintenance

- Safety Protocols

- Process Optimization

- Team Training

- Production Scheduling

Education

Master of Science Mechanical Engineering

University of Illinois Urbana-Champaign, Illinois

June 2019

Bachelor of Science Industrial Technology

Illinois State University Normal, Illinois

June 2017

Certifications

- Certified Machine Operator - Manufacturing Institute

- CNC Machining Certification - National Tooling Association

Languages

- Spanish - Beginner (A1)

- German - Beginner (A1)

- French - Beginner (A1)

Must-Have Skills on a Machine Operator Resume

A robust skills section is important for making your resume stand out in competitive job markets.

Skilled trade professionals bring practical expertise and reliability to essential tasks. The skills you highlight should reflect your ability to perform consistently and support quality work. Your resume allows you to show how you contribute to durable results and the smooth functioning of vital operations.

The following data illustrates the most prevalent hard and soft skills for machine operators based on our internal research at Resume Now.

When you're ready to improve your resume with relevant skills, check out the AI Resume Skills Generator. It offers tailored suggestions for both hard and soft skills according to your job title, ensuring a comprehensive skill profile.

Writing Your Machine Operator Resume

Having explored these effective resume examples, you are now prepared to dive into the details of how to write a resume. We will walk you through each section so you feel confident and ready to create your own standout document.

List your most relevant skills

An effective skills section for a machine operator resume should focus on both technical abilities, such as skill in operating machinery and understanding safety protocols, and essential soft skills like teamwork and attention to detail. This section is your chance to demonstrate how well you can meet the demands of the role.

Make sure to read the job listing carefully and incorporate keywords from the job listing into your skills section. By aligning your skills with what employers are seeking, you not only appeal to human recruiters but also improve your chances with applicant tracking systems.

Example of skills on a machine operator resume

- Proficient in operating various machinery and equipment with precision

- Strong understanding of safety protocols and regulations in manufacturing

- Effective communicator capable of collaborating with diverse teams

- Adaptable and quick to learn new processes and technologies

Highlighting your soft skills on your resume can set you apart from other applicants. Employers greatly appreciate interpersonal abilities, as they are often more challenging to develop than technical expertise, making them a valuable asset in any role.

Highlight your work history

An effective work experience section showcases how you have applied your skills in practical situations, emphasizing results and contributions that demonstrate your value to previous employers.

For each job entry, be sure to include essential details such as your job title, the name of the employer, and the dates of employment. These components provide a clear timeline of your career history and establish your credibility in the field. Highlight specific accomplishments that illustrate your skill with machinery and adherence to safety protocols.

Example of a machine operator work experience entry

- Machine Operator

XYZ Manufacturing Inc. - Houston, TX

June 2019 - Present - Operate and monitor heavy machinery to ensure optimal production efficiency, achieving a 15% increase in output over the past year

- Perform routine maintenance on machines, identifying and resolving issues proactively to minimize downtime by 25%

- Collaborate with team members to implement safety protocols, leading to zero workplace accidents for two consecutive years

- Train new operators on equipment handling and best practices, improving team productivity by streamlining onboarding processes

- Analyze production data to identify trends and suggest improvements, contributing to a reduction in waste material by 10%

Focus each bullet point on a specific achievement. Be concise, but include enough detail to highlight your impact and skills.

Include your education

The education section of your machine operator resume should list your credentials in reverse-chronological order, starting with the most recent degree or certification. You can exclude your high school diploma if you have completed higher education such as an associate degree, certificate, or trade school program relevant to machine operation.

If you are currently enrolled in a program or have not yet completed your education, it's important to mention your highest achieved level along with an anticipated graduation date. Additionally, showcasing relevant coursework or hands-on training can provide valuable insights into your qualifications for the role.

Common certifications for a machine operator resume

- Certified Production Technician (CPT) – Manufacturing Skill Standards Council (MSSC)

- Forklift Operator Certification – National Safety Council (NSC)

- Lean Six Sigma Green Belt – American Society for Quality (ASQ)

- Machine Safety Certification – OSHA Training Institute (OTI)

Sum up your resume with an introduction

Creating a powerful profile section on your resume is essential for making a strong first impression. It serves as your personal pitch, showcasing your career highlights or aspirations right at the start.

For seasoned applicants in the manufacturing field, a professional summary is particularly effective. This format allows you to quickly summarize your most significant achievements and skills, demonstrating to hiring managers that you possess both experience and expertise. If you don't yet have much experience, include a resume objective that focuses on your aspirations and development.

Professional summary example

Accomplished machine operator with over 8 years of experience in high-volume manufacturing settings. Demonstrated expertise in optimizing production processes, reducing downtime, and ensuring quality control. Proficient in operating CNC machinery, troubleshooting mechanical issues, and adhering to safety protocols to improve operational efficiency.

Resume objective example

Enthusiastic machine operator eager to use hands-on experience and technical acumen to support efficient production processes at a forward-thinking company. Committed to applying strong attention to detail and problem-solving skills to improve operational efficiency and ensure high-quality output.

As a machine operator, your resume profile should be succinct but packed with critical information. Aim to keep it to three sentences that highlight your most relevant skills and experiences. If there are additional details you'd like to expand upon, consider including them in your cover letter.

Add unique sections to set you apart

Incorporating optional resume sections can help you highlight your unique qualifications as a machine operator. These sections provide an opportunity for you to stand out by showcasing skills and experiences that might not fit into traditional categories.

Think about including relevant hobbies or volunteer work that align with the values of your profession. For example, if you enjoy tinkering with machinery in your spare time or actively participate in community service related to safety practices, these activities reveal your commitment and practical skills.

Three sections perfect for a machine operator resume

- Technical Skills: Technical skills are important for a machine operator's resume. They demonstrate your capability to handle machinery and equipment safely, ensuring efficiency and precision in production processes. Highlighting these skills can set you apart from other job seekers.

- Tools and Platforms: In today's manufacturing environment, skill in various machinery and software is essential. Highlight your computer skills with CNC machines, production management software, and quality control systems to improve efficiency and accuracy on the job.

- Professional Certifications: Certifications showcase your dedication to skill enhancement in technical roles. Pursue relevant certifications to boost your expertise, credibility, and career advancement opportunities in the competitive job market.

5 Resume Formatting Tips

- Choose a format that matches your career stage.

Selecting the right resume format is important for showcasing your skills and experience effectively. If you're an experienced machine operator, a chronological resume highlights your work history. For those just starting out, a functional resume emphasizes relevant skills. Consider a combination format if you have varied experiences to present.

- Pick a smart resume template.

Using a professional resume template improves readability and helps you stand out. A well-structured layout allows hiring managers to quickly glance at your qualifications. If you prefer to create your own format, ensure it remains clean and uses fonts that are friendly to applicant tracking systems.

- Select an appropriate font.

Choose a professional font like Verdana, Helvetica, or Georgia to improve resume readability. These fonts ensure both ATS compatibility and a polished look for human reviewers.

- Use consistent formatting.

Ensure your resume is neatly aligned to the left with uniform margins. This creates a polished and professional look that attracts employers' attention.

- Keep your resume to one or two pages.

When crafting your resume, remember that resumes should be one page long unless you have extensive experience. Keep your content concise and focused to highlight your skills effectively.

What’s the Average Machine Operator Salary?

Machine operator salaries vary based on location, career level, and qualifications.

This data, provided by the Bureau of Labor Statistics, will show you expected salary ranges for machine operators in the top 5 highest-paying states, including the District of Columbia. The figures reflect the most current salary data available, collected in 2024.

- Full Range

- Most Common (25th–75th percentile)

- Average

Wyoming

Most common: $86,330 - $109,300

Alaska

Most common: $73,300 - $89,840

Wisconsin

Most common: $82,180 - $93,220

Nevada

Most common: $83,400 - $84,780

Virginia

Most common: $76,120 - $84,430

Tools for Your Job Search

Are you ready to apply for that machine operator position you've been eyeing? Before you send in your application, consider using our ATS Resume Checker. This powerful tool provides essential feedback on how well your resume is likely to perform with the automated systems that many manufacturing companies use for initial screening.

Looking for a way to make your resume stand out? Our AI Resume Builder offers tailored content recommendations specifically designed for machine operators, along with professional templates that showcase your technical skills and experience effectively.

Frequently Asked Questions

Last Updated: November 5, 2025

Absolutely. A cover letter is important because it adds depth to your resume and creates opportunities for you to communicate directly with employers. It’s your chance to express what draws you to the machine operator role and how your unique skills make you a perfect fit. Don’t overlook this key step—write a cover letter that improves your application.

If you're looking for a quick way to craft a strong cover letter, try our AI Cover Letter Generator. It allows you to create tailored letters in minutes and offers various cover letter template options that will match your resume perfectly, making your application stand out effortlessly.

Resumes are generally concise documents that span one to two pages, highlighting your skills and experiences in a brief format. In contrast, a curriculum vitae (CV) can extend for several pages, offering detailed insights into your academic background, research contributions, publications, and extensive professional experience.

You should use a CV when applying for specialized positions in academia or fields such as science and law. If you need to prepare a CV quickly and efficiently, our online CV Maker is the perfect solution. With various tailored CV templates available for different industries and career levels, creating a standout CV has never been easier.

Indeed, essential skills like "machine maintenance" and "safety compliance" are important on machine operator resumes. It’s also beneficial to review job descriptions for additional keywords that employers prioritize in this role.

To build an effective skills section as a machine operator, highlight your technical skills such as machinery operation and maintenance alongside soft skills like teamwork and problem-solving. In your experience section, detail how these skills helped improve efficiency or reduce downtime in previous roles to showcase your contributions.

Customize your machine operator resume by highlighting the essential skills needed for the job you want. Review job postings to find keywords that reflect what employers seek, then integrate them into your resume to show how you fit the role perfectly.

As a machine operator, showcasing your dedication to continuous growth is essential. You can achieve this by obtaining relevant certifications and highlighting any courses you’ve completed. Attend industry seminars, read insightful books, listen to relevant podcasts, and join professional associations. These actions not only prove your commitment but also keep you informed about the latest trends in your field.

Was this information helpful? Let us know!

Hailey is a career advice writer dedicated to helping job seekers excel in their careers.

More resources

How to Make a Canadian Resume (Format, Template + Examples)

Creating a Canadian resume is key to getting a job in Canada. ...

How to Write a Resume for an Internal Position (Guide + Examples)

Ready for a new role within the same company? We ll help you...

The Great Workplace Reckoning: How 2025 Burned Out Workers & What’s Next for 2026

The workforce spent much of 2025 in survival mode navigating ...

Interview-Winning Data and Systems Administration Resume Examples and Tips

Was this information helpful? Let us know ...